OEM family for all sample quality measurements

Posted by:

Konstantin Lutze

Published on:

Feb 2, 2024

The quality control of samples is increasingly becoming a must-have, particularly for the so-called omics applications. Based on the intelligent sample handling of the eviDense UV measurement module, we are developing a whole family of detection units.

These can be seamlessly integrated into liquid handling systems and are suitable, among other things, for the analysis of DNA, RNA, and protein samples, fluorescence emission measurements, and cytometry. Manufacturers have the opportunity to effortlessly expand their instruments through established and efficient analysis methods within an OEM model offered by HSE•AG, even for already installed devices.

Quality control and quantification of samples are essential for the reliability of results in downstream analysis workflows. This is particularly true for applications based on DNA/RNA analysis. According to our conversations with users of these technologies, we recognize a growing need for reliable and automated procedures for determining sample quality.

Quality control is becoming a standard requirement

Systematic quality control of samples will become standard in the coming years, and not only in the NGS (Next Generation Sequencing) environment. Manual quality control after sample preparation often falls victim to time pressure, particularly with semi-automated solutions. The resulting substandard downstream application is doomed to fail. Automation and integration of quality control could prevent this.

Foundation of a comprehensive family of detection modules

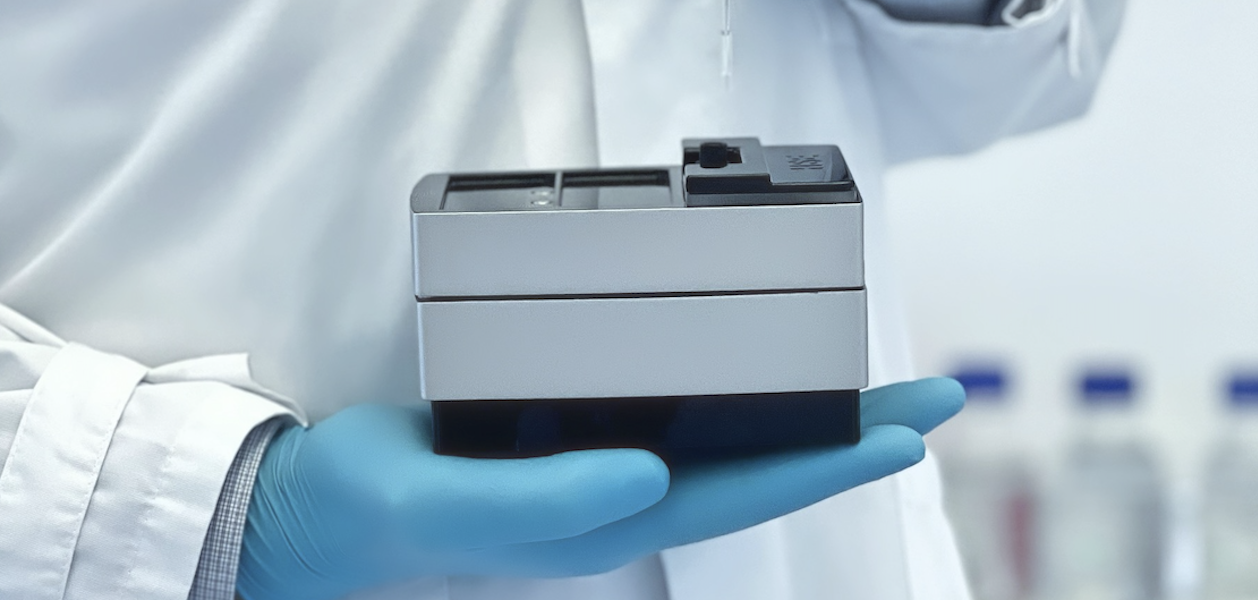

With eviDense UV, we have developed an innovative OEM module that enables manufacturers of liquid handlers to seamlessly integrate the concentration and quality measurement of nucleic acid samples into their devices using optical density measurements in the UV range.

The same intelligent sample handling that enables eviDense UV to perform accurate measurements without loss of sample material will form the basis for an entire family of OEM measurement modules in the future. The next step is to enable fluorescence-based detection and optical density measurement in the visible spectrum.

Disposable cuvettes prevent contamination

Disposable measuring cuvettes form the centrepiece of the sample handling system. The cuvettes are injection molded in COC ensuring UV-transparency down to 200nm. They are designed so that they can be picked up by the pipette tip of a liquid handler. This allows for transport of the cuvettes with the pipette tip to the detection unit. There, approx. 10 microliters of the sample previously aspirated by the tip are dispensed into the cuvette. After measurement, the full volume of liquid can be aspirated back into the tip and – if qualified “fit for use” - directly pipetted in the downstream process. This process prevents contamination and ensures that the sample material is completely preserved.

Compatible with diverse measurement methods

Another major advantage of this kind of sample handling is that it can be combined with virtually any kind of optical detection technology. For example, to determine protein concentration, a detector can be integrated that measures the intensity of a biuret assay at 550 nanometers.

Fluorescence emission detectors enable highly sensitive measurements that can be used to determine the proportion of single- and double-stranded DNA, among other things. A spectrometer that records a complete spectrum of 230–1100 nanometers can be used to analyze metabolites.

Upgrade instruments with new functions

Manufacturers of liquid handlers will be able to use the modules as an OEM model. This gives them the opportunity to easily equip their range of instruments with these important, established analysis methods and to create decisive added value for customers. An easy upgrade of already installed devices is also possible, as the module is easily connected via a USB-C connector.

Discover more about our eviDense UV DNA quality measurement module.

Contact us

What are your thoughts on sample quality measurement? Discuss them with our expert Konstantin Lutze and learn how a cuvette-based sample handling method could also be used in your instruments.

About the author:

Konstantin Lutze has more than 25 years of experience in the development of laboratory automation and in-vitro diagnostics systems. Before becoming CTO of HSE•AG, the electrical engineer was VP Instrument Development at QIAGEN, where his responsibilities included the successful development and market launch of a next-generation sequencing platform. As CTO, he is now responsible for technology management and drives innovation in the field of nucleic acid, protein and cell analysis, which enables HSE•AG to offer its customers decisive added value.